For decades, conduit has been the default answer for cable protection and strain relief. But in many real-world applications, it’s also one of the most expensive and labor-intensive parts of an install. More contractors and OEMs are starting to ask a simple question:

Do we really need conduit here?

In many cases, the answer is no and cable grips are the reason and solution.

The Hidden Cost of Conduit

Conduit isn’t just pipe. It’s a money drain:

💰material costs (conduit, fittings, couplings, supports)

💰significant labor for bending, cutting, threading, and mounting Increased installation time and coordination

💰limited flexibility when layouts change

For short cable runs, drops, equipment connections, or strain-relief-focused applications, conduit can quickly become overkill.

Where Cable Grips Change the Equation

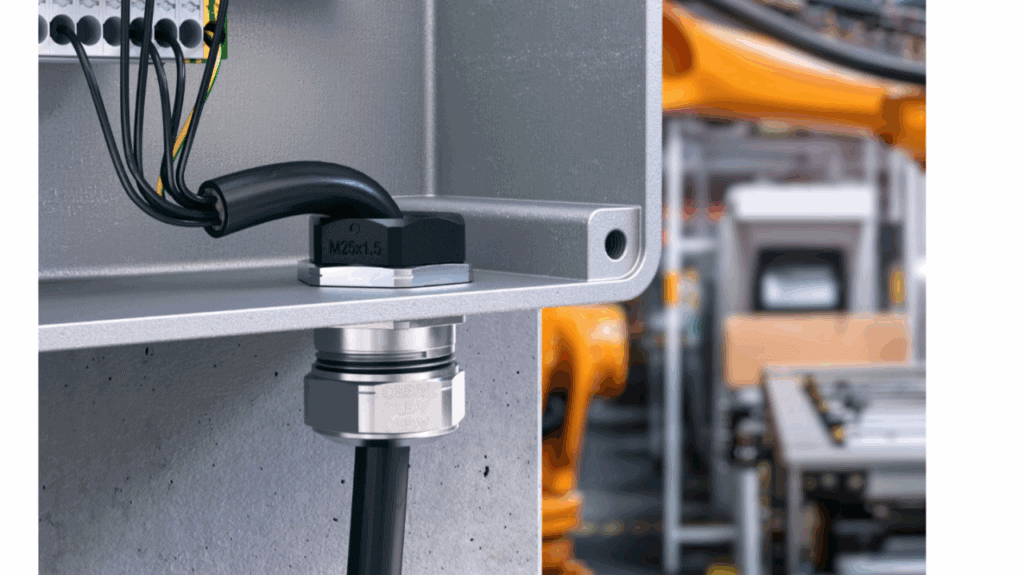

Cable grips provide mechanical strain relief and cable support without the bulk and expense of conduit systems. When properly selected, they:

✅ Secure and protect cables at termination points

✅ Absorb tension, vibration, and movement

✅ Reduce wear on conductors and connections

✅ Eliminate the need for rigid raceways in many applications

✅✅✅ The result is a simpler, faster, and more adaptable installation.

American Electrical, Inc., (AEI) stocks and sells the AGRO line of Cable Grips – in NPT, Metric, PG and Gas thread types as well as in Nickel Plated Brass, Nylon, Aluminum and Stainless Steel. Call us at 804.379.2899 for a quote today