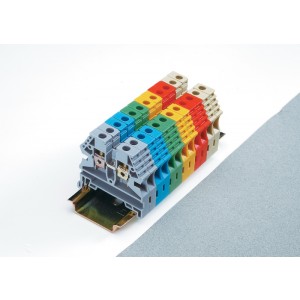

Is our AVK series right for your application? Check out all of American Electrical's terminal block options here.

Similar to Phoenix Contact Terminal Blocks (screw clamp).

Is our YBK series right for your application? Check out all of American Electrical's terminal block options here to be sure.

Similar to Wago terminal blocks (tension clamp).

Is our PIK series right for your application? Check out all of American Electrical's terminal block options here to be sure.

Is our PUK series right for your application? Check out all of American Electrical's terminal block options here to be sure.

See our video on disconnect terminals here.

See our video on disconnect terminals here.

Click here to see a video on our DIN rail mounted Thermocouple Terminal Blocks.

**This video not only shows you how to terminate thermocouples but also how you can plug directly into the terminal block with your handheld device to read process temps or calibrate the control system.**

See our video on disconnect terminals here.

Is our WGO series right for your application? Check out all of American Electrical's terminal block options here to be sure.

Click here to see the video on our safe and reliable way to make circuit connections with safe circuits.

We offer a complete line of DIN Rail mounted components – Including Terminal Blocks, Power Supplies, Fuse Holders, Circuit Breakers, Interface Modules and Disconnect Switches. We also sell Printed Circuit Board Terminals and Connectors, Wire Ferrules and Tools for Crimping Ferrules and Cable Grips.

International Shoppers

View Full Catalog

@AmericanElecInc

YouTube Videos

American Electrical, Inc. is a proud sponsor and Mentor of the Midlothian High School Robotics Team #1541.